Industry:Packaging and Labeling Added By:Admin Posted On:Aug. 9, 2019

Packaging and Labeling of any commodity generally involves a lot of mundane tasks such as generalizing and bifurcating the constituents undergoing packaging, consolidating every constituent with its legal validation and regulatory compliance, harmonizing other various requirements concerning the brand and advertisement and how to execute them in the labeling process, etc. These are very few to mention, but, the list of real challenges faced in packaging and labeling process, goes on and on and is endless. Below mentioned are the major challenges that are faced by the packaging and labeling industry in various sectors, including pharmaceuticals, which demands optimum solutions, for an easy packaging and labeling process.

Delays caused in the packaging and labeling process due to manual tasks

With major companies lacking the digital or the advanced equipment to conduct the packaging and labeling process easily, they conveniently rely on the manual process that takes forever to accomplish the task and causes delay for the commodity to reach its destination. The pharmaceutical industry is one amongst the major industries to face delays in the production process due to the time complications in the packaging and labeling process. There are other factors as well, which contributes to the packaging and labeling process in the pharmaceutical industry, such as space availability and outsourcing the artwork produced for the packaging and labeling process.

Meeting the authoritative regulatory requirement along with the brand's

The development of digitization has caused various companies coming up with their design and structure to make their products look variant and attractive, along with a motive to reach a wide number of customers in a short time. However fruitful it might seem for an industry giving a variety of options to its consumer by bringing diversity in the looks of packaging of a commodity, it takes a huge toll on the people involved in designing and constructing the label that makes it look more appealing to customer and enhances the brand image and market value, extensively. To make the designing process more complicated, the artwork production team have to necessarily be compliant with the stringent regulatory requirement set by the authority governing the packaging and labeling industry and also achieve the necessary branding requirements by the brand owners to promote the marketing of their products, altogether.

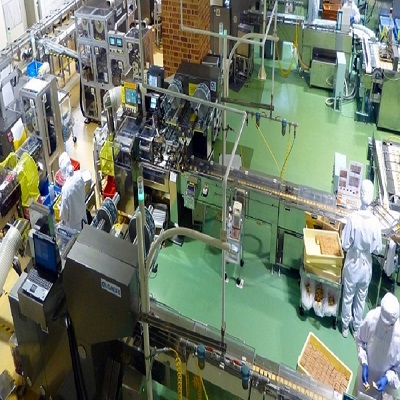

Installing automated machine enhanced packaging can cost a fortune

When a firm owns an in-house artwork production, i.e., its packaging and labeling department rather than outsourcing it, the process becomes less time-consuming, cost-efficient, and reduce the overhead of the company to spend a huge amount on an outsourced production service. Shifting to a fully automated means of packaging and labeling can be costly, as it requires the installment of various advanced equipment that make the packaging and labeling process much easier and less time consuming, which another major challenge that is faced by the packaging and labeling industry. The automated packaging and labeling process implements a routine communication between one process and another and prevents the mishap of printing one label to another. This produces a large number of packaged item in a very short time and is less cumbersome compared to the manual packaging process.

Accommodating the brand and other country's regulatory requirements in multiple languages

Advertising and marketing a brand in a country, where English is not a native language, requires the packaging and labeling process to be done in compliance with that country's regulatory norms and its native languages such as French, German, Spanish, etc. This is more complex in itself than it sounds. The organization, which owns an in house artwork production, must also own multi-lingual employees working for designing as packaging and labeling. Well if not, it should consider to hire an employee, who not only speaks more than one languages but, can also read and write them quite fluently, as any native would do. Hiring a multi-lingual employee adds extra investment from the organization, expanding the organization's expenditure. These can double the packaging and labeling as compared to the process taking place in just the English language. Another major issue that comes along with the multi-lingual language is the confined amount of space and the choice of the container in which the label is going to be applied for advertisement.

The industry considers this as a hectic process as it needs to decide the size of the container, should fill in all the regulatory requirements such as the child policy, number of dosages, age policy, information about the medications, and nutritional facts, along with the ingredients. Upon this, choosing the interactive color and complying with the medical standards (for medicinal packaging and labeling) is another succulent task faced by the packaging and labeling industry. To meet the safety requirements, it is necessary that the packaging and labeling of the commodities must be done with the utmost care and preventing any mishaps, thus including how to use and how to dispense after use is another important paradigm that should be included in the labeling process. It now becomes a cumbersome and a hectic task to fulfill these requirements in a very short time and produce the quantity in large number.

The effectiveness in the packaging and labeling comes with continues regulation on quality, quantity, and safety. Complying with all the requirements and regulatory needs and acing the three factors of quantity, quality, and safety, the industry can thus carry out the process easily. Automating the packaging and labeling process, with the latest technologically advanced machines, the process can be made less time-consuming, cost-effective, and less tiring with very little to no physical requirements.